Anyone who has spent time out in the bush knows that the reliability of the gear you choose is paramount to both safety, and having a good time. The suspension in your vehicle is no exception. This month we find out how Tough Dog foam cell shocks – which add safety, durability and comfort to that overland trip – are manufactured.

Let’s face it, everybody wants to arrive at their destination in one piece but nobody wants to arrive with a fused spinal cord from a rough ride. We know that suspension plays an important part in comfort, capability and safely keeping your wheels on the road. Foam cell shock absorbers help to reduce shock fade by keeping nitrogen gas and oil found inside the shock, separated. So what is a foam cell shock, and why is it so resilient?

All shock absorbers contain oil, with some choosing to insert nitrogen gas, too. When the shock works hard, the oil heats up and expands, and the gas contracts to allow this to happen. In traditional nitro gas shocks, the gas is placed in the shock on top of the oil, with no separation. This is called an emulsion shock. While the shock is working, the oil and gas can be mixed together by the action of the piston. When the gas bubbles pass through the valve assemblies in the shock absorber, the lesser viscosity causes the shock to fade, and fail to perform.

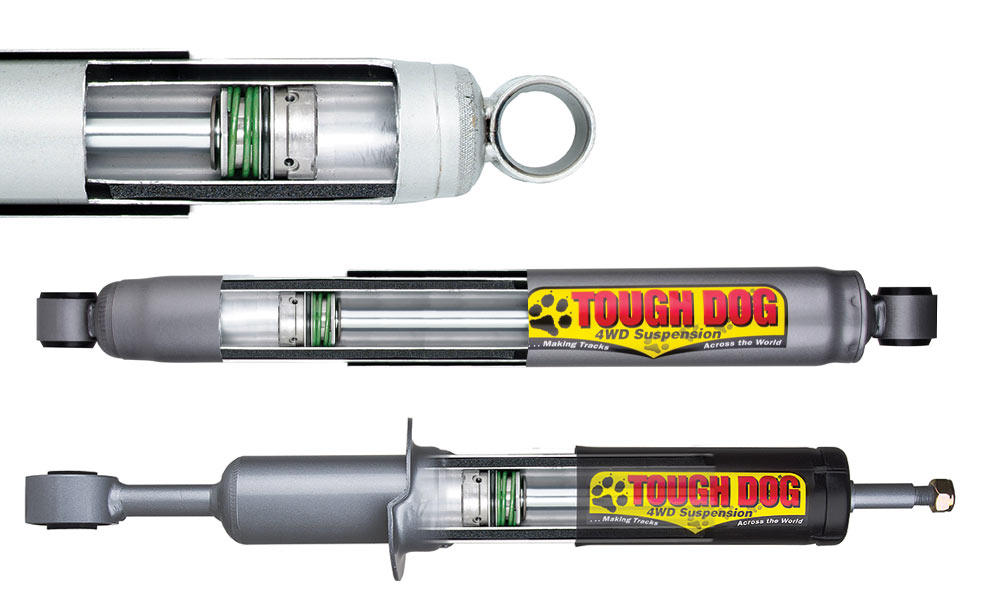

The foam cell contains the nitrogen gas in bubbles within the foam, so it continues to perform its task in regulating the pressure of the oil, but because it is trapped within the foam, it cannot mix with the oil. It is in this way that the foam cell shock guards against aeration, and has superior resistance to fade. Here’s how Tough Dog’s award-winning 41mm foam cell shock absorbers are made.

1: The outer body is made from sheet steel, is rolled, then seam welded to size. Rolling the tube and seam welding is a traditional, cost-effective way of making the tube. Tough Dog shocks are a twin-tube design, meaning that the outer body tube contains oil, but is not part of the piston’s working surface. If the application demands it, the ends of the newly formed tube are swaged to size.

2: While the shock body is being formed, the shock absorber rod is formed from mild steel. The rod begins life on a cotton reel and is drawn out, stretched and cut into one-metre lengths. The stretching process helps to straighten the rod, and is integral to giving the steel its core strength.

3: The drawn and straightened rod is then parted on a lathe to predetermined lengths. Thread is then cut into the end of the rod in preparation for the piston to be fitted further down the line.

4: The parted rods are cleaned thoroughly and put through heat treatment in preparation for chrome plating. The heat treatment is also the last stage of the strengthening process for the rod. The 41mm foam cell shock uses an 18mm diameter rod for maximum strength to guard against being bent by the forces of off-road use.

5: At this stage, the rod is handled in a manner akin to the royal jewels. Each rod is placed between layers of protective material. Any impact, chipping or other mark on the chrome rod plating can ruin the rod and render it useless. From this point on, the shock is assembled in a clean room environment with the highest care.

6: The rod is held with Teflon (which doesn’t mark the surface) and the piston head and valve arrangement is threaded onto the end of the rod, and staked in place. The staking process stops the piston from unwinding from the rod end, which would lead to knocking and performance issues from the finished product. Travel-limiting devices are installed to the rod also to ensure that the piston assembly does not come into contact with the top body seals in the shock during use. Tough Dog 41mm foam cell shocks are fitted with Teflon stop rings.

7: While all this has been happening to the heart and soul of the shock absorber, the outer shell has not been sitting idle. The base cup piece is welded by robot to the bottom of the outer tube. The newly united assembly is flipped upside down and placed in water. Pressure is then introduced to the cylinder to test the weld to ensure it is completely watertight.

8: The inner tube, the working cylinder, is parted to length from seamless tube. Seamless tube is used for the inner working tube for its accuracy in manufacture. The foot valve assembly is pressed into place in the base of the inner tube. The inner tube and foot valve are placed into the outer tube.

9: One of the most important pieces, the foam cell, is made by pressure injecting nitrogen gas into the foam in large sheets. A pre-cut piece is inserted between the inner and outer tubes. The shock is then filled with oil.

10: The marriage of the piston and rod assembly to the tubes is the link in the chain. The top body assembly is put in place to hold everything together. Tough Dog shocks receive a DU bearing, to ensure the shock rod runs straight up and down, and to guard against side load damages. This is followed by multi-lip oil seal and the dust scraper seal.

11: With the top cap in place, the shock goes through a quality assurance check. Before it is welded or folded closed, the shock is dyno graphed to ensure it performs to the specification. Any mishaps in the piston head valving, or from the foot valve will show up as being different in pressure response to the specified tolerances.

12: Shocks that pass the test get the green light to move on to final welding of the top cap, which is performed again by robot. Once welded shut, the shock is on the home straight. After thorough cleaning and heat treatment to completely dry the surface, the shock goes through a multi-layer paint process, following by a heat treatment to dry and set the paint layer.

More information: oppositelock.co.za

Text: David Cook Photographs: Tough Dog 4WD Suspension