To understand how electronic traction control systems work, one has to start with the anti-lock braking system, or ABS.

But why kick off with technology that’s been around since 1929, first developed for aircraft? Because ABS holds the key to traction control, and for that matter many of the other technologies in use today to improve active safety in cars.

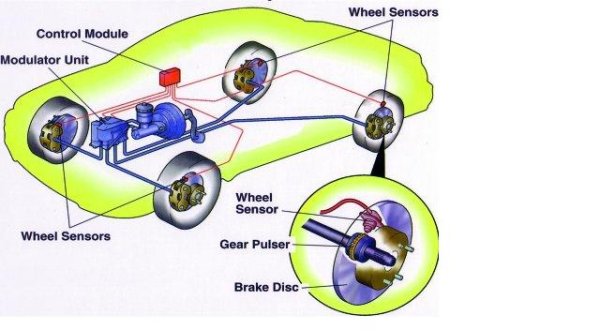

A typical ABS is composed of a central electronic unit, four wheel speed sensors (one for each wheel), and two or more hydraulic valves on the brake circuit. The electronic unit constantly monitors the rotation speed of each wheel.

hydraulic valves on the brake circuit. The electronic unit constantly monitors the rotation speed of each wheel.

When it senses that any number of wheels are rotating considerably slower than the others (a condition that will bring it to lock) it moves the valves to decrease the pressure on the braking circuit, effectively reducing the braking force on that wheel.

The wheel(s) then turn faster and when they turn too fast, the force is reapplied.

If this sounds like “what’s the big deal”, it’s good to remember that the brake-and-release process happens 20 times a second! It’s repeated continuously until the emergency is over, this process causes the characteristic pulsing feeling through the brake pedal.

In vehicles not equipped with ABS, the driver has to manually pump the brakes to prevent wheel lockup, a technique known as cadence braking. In vehicles with ABS, your foot should remain firmly planted on the brake pedal, while ABS pumps the brakes for you so you can concentrate on steering to safety.

That brings us to traction control. The same ABS system is also utilised to brake a wheel that starts spinning on a slippery surface.

But why, and how will it help you to get out of a sticky situation?

Again we have to go back to technology that’s been around since more or less the invention of the motor vehicle – the differential.

As the name suggests (or doesn’t!) the differential is used in the drivetrain to compensate for the difference in wheel speeds when a car goes around a corner. If you have a locked unit, the inner wheel – trying to turn at the same speed as the outer that has to travel farther – will start spinning, with resulting axle windup.

Without going into the technical bits: The differential is thus designed to, in a corner, disengage the axle of the wheel with the most resistance, the inner one, and send power to the one with least resistance – the outer wheel – to help the car get around the corner.

So, when you get into a slippery situation off-road and one of the driving wheels loses traction and starts spinning while the other is standing still, the differential “thinks” the vehicle is rounding a corner. It then disengages power to the wheel standing still or turning slowly – in other words the one with grip. And there you stop.

That’s why vehicles with mechanical 4×4 systems usually come with a differential lock to join the two axles together and send equal power to both wheels.

In the case of electronic traction control the system uses – you guessed it – the anti-lock braking system.

When the sensors detect the difference in wheel speeds, the ABS is used to slow down the spinning wheel. This might be enough to regain grip, but at the same time the differential “thinks” that the car is again straightening out after the “corner” and sends power to the wheel with grip.

Experienced 4×4 drivers also use this principle to keep going, by using the brake pedal or handbrake of a vehicle without diff lock or traction control to brake a spinning wheel and transfer power to the other.

In theory then, a four-wheel-drive vehicle with traction control can start moving again even if just one wheel has traction. In practice, probably not.

That’s why it’s important to know how to drive a vehicle with traction control off-road, as opposed to a “proper” 4×4 with permanent or selectable four-wheel drive.

Firstly, momentum is crucial. Not to be confused with speed, however, although you will be travelling a little faster than you would with a low-range equipped 4×4. If you can keep the vehicle moving forward, the traction control system has the best chance to transfer power in such a way that traction is not lost completely.

The biggest mistake drivers of these vehicles make is to lift off the accelerator when there’s a loss of traction, or when they hit a bump on the way up the incline. That’s when the vehicle comes to a stop, and it’s usually difficult to pull off again.

It’s important to keep on accelerating when traction is lost. Not foot flat, but just a steady supply of power so that a wheel can start spinning and the traction control can come into play.

Better still, if you can, to go back and attack with a little more momentum.

Many of these “soft-roader” 4×4 or crossover utility vehicles are much more capable than they appear, but without low range they certainly aren’t bundu bashers. Driven sensibly, though, they will take you far off the beaten track.